Offices, industrial facilities, institutions and other settings all can make use of plastic nameplates. Nameplates are also commonly affixed to tools, large equipment and automobiles to indicate brand names. Some varieties can even be affixed to clothing and used as nametags. Read More…

At STRYKER, we take pride in designing and manufacturing precision name plates that serve as both identification and branding tools for a wide range of industrial and commercial applications. We understand that name plates are more than simple labels—they represent a company’s identity, quality, and attention to detail.

We are a manufacturer of identification products for original equipment manufacturer’s and utilities. For 75 years we have made pole tags, cable markers, data plates, safety signs and all things identification. Tech Products, Inc. provides the most durable products in our industries with brand names like EVERLAST, Tech-3D, FASTTAG, and TechBrite. We are also a service company – an information ...

At Nameplate & Panel Technology, we are proud to be a leading provider of high-quality nameplates and panel solutions that meet the diverse needs of businesses across various industries. With decades of experience and a commitment to innovation, we have earned a reputation for excellence in the field of custom identification and labeling.

JN White is an ISO 9001:2015 and ITAR-certified manufacturer of name plates, graphic overlays, and custom labels. We nimbly handle projects big and small and have the uncommon ability to translate what our customers need into high-quality, high-precision outcomes. Our team's goal is to bring you the best through our dedication to quality and our constant pursuit of the latest technology. contact...

More Plastic Nameplate Manufacturers

Plastic Nameplates: Versatile Identification Solutions for Businesses and Organizations

Plastic nameplates serve as durable, cost-effective identification tools in a wide variety of settings, from commercial offices and industrial facilities to educational institutions and healthcare environments. Leveraging the latest in plastic fabrication and engraving technologies, these custom nameplates offer flexibility in design, outstanding value, and reliable performance, making them a preferred choice for businesses seeking to streamline their identification and signage systems.

What Are Plastic Nameplates?

Plastic nameplates are identification tags or signs manufactured from high-quality plastic materials. These plates can be customized with names, numbers, logos, or other information, and are commonly used for employee identification, room numbers, directional signage, equipment labeling, and branding applications. Compared to traditional materials such as wood, aluminum, or brass, plastic nameplates are lightweight, affordable, and resistant to corrosion and environmental wear.

Why Choose Plastic Nameplates?

Businesses and organizations choose plastic nameplates for numerous reasons, including their:

- Affordability: Plastic nameplates are an inexpensive alternative to metal and wood, making them ideal for bulk orders or large-scale installations.

- Durability: Resistant to moisture, UV radiation, chemicals, and tarnishing, plastic nameplates maintain their appearance over time, even in demanding environments.

- Customizability: Options for color, texture, size, shape, and font style are virtually limitless. Plastic materials can be engineered to match branding specifications or aesthetic requirements.

- Lightweight Construction: The reduced weight of plastic nameplates simplifies installation and minimizes load on mounting surfaces.

- Low Maintenance: Unlike metals that may rust or tarnish, plastic nameplates require minimal upkeep and are easy to clean.

- Versatile Mounting Options: They can be attached with adhesives, screws, or magnetic strips, and are compatible with various surfaces, including doors, walls, desks, and machinery.

Common Applications for Plastic Nameplates

Searching for the right nameplate solution for your business or facility? Explore these popular applications for plastic nameplates:

- Office Nameplates: Clearly identify workspaces, offices, and cubicles with custom-engraved plastic nameplates.

- Door Nameplates: Indicate room names, numbers, or designations on doors in schools, hospitals, hotels, and apartment buildings. Explore door nameplate options.

- Desk Nameplates: Personalize employee desks with professional, branded nameplates that reinforce company culture and organization.

- Restroom and Wayfinding Signage: Use color-coded and symbol-engraved plastic plates to direct visitors and staff efficiently, often utilizing blue backgrounds for restroom indicators.

- Machinery and Equipment Labels: Identify assets, safety instructions, or operational guidelines on industrial equipment with durable, chemical-resistant nameplates.

- Nametags and Badges: Create cost-effective, reusable employee ID badges for events, conferences, or ongoing use.

- Branding and Marketing: Enhance brand visibility on products, vehicles, or promotional displays with customized logo nameplates. For more details, learn about leading nameplate manufacturers.

Types of Plastic Used in Nameplates

The choice of plastic material influences the appearance, durability, and application of a nameplate. The most common plastics used include:

- Acrylic: Known for its clarity and gloss, acrylic is often used for upscale office or retail nameplates, offering a glass-like look with shatter resistance.

- Polycarbonate: Highly impact-resistant and suitable for harsh environments, polycarbonate nameplates are common in industrial and outdoor settings.

- ABS (Acrylonitrile Butadiene Styrene): Offers excellent toughness and is easy to engrave, making it a popular choice for desk nameplates and equipment tags.

- PVC (Polyvinyl Chloride): PVC nameplates are versatile, weather-resistant, and cost-effective, ideal for indoor and outdoor signage.

- Engraving Laminate: These dual-layer plastics are specifically designed for laser or rotary engraving, revealing a contrasting color beneath the surface for highly readable text and graphics.

How Are Plastic Nameplates Manufactured?

Plastic nameplate production involves several advanced processes, each tailored to maximize quality and customization. Common manufacturing methods include:

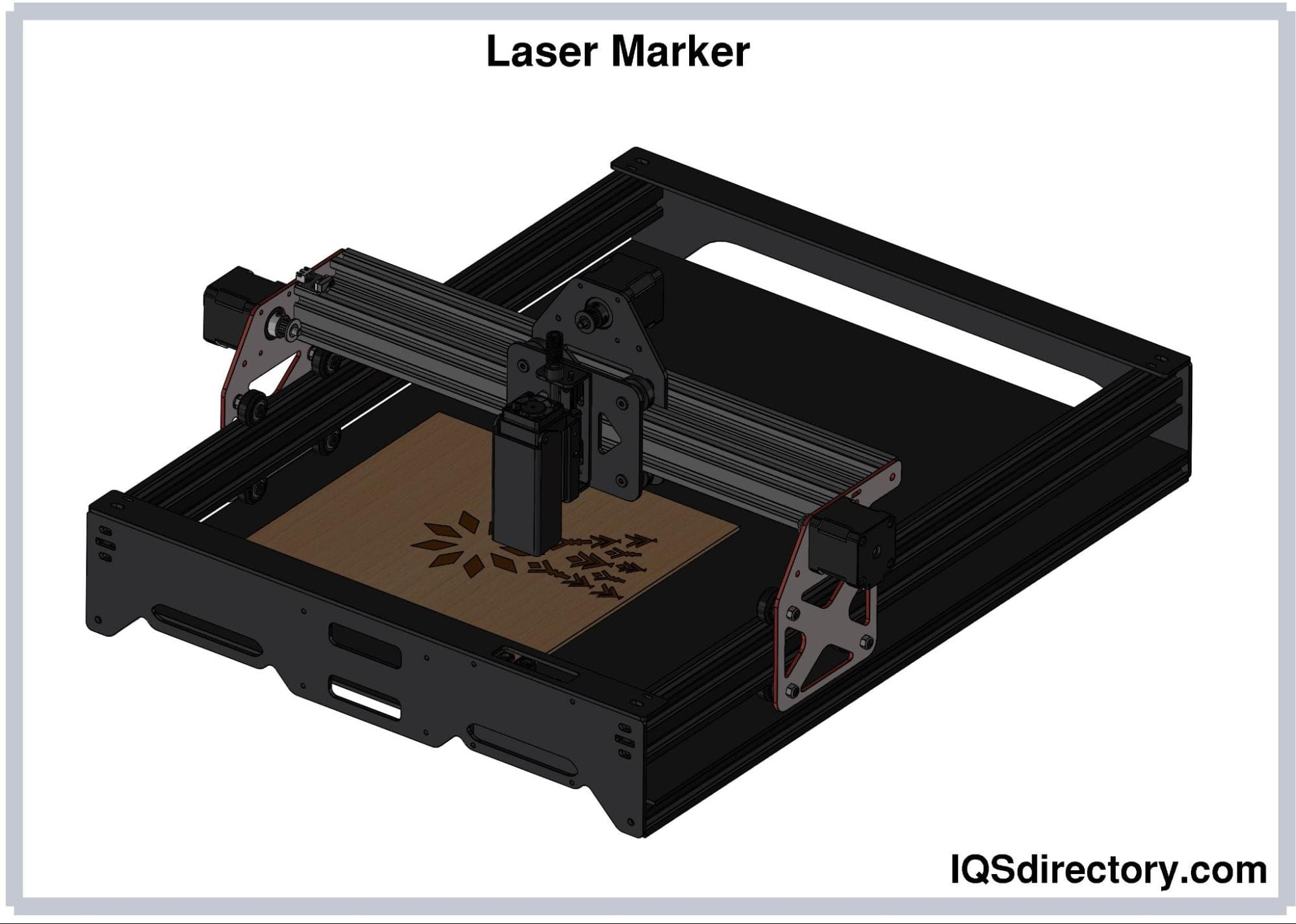

- Laser Engraving: A precise, computer-controlled process in which a laser beam removes material from the surface, creating crisp, permanent markings. Laser engraving is ideal for intricate logos, serial numbers, and variable data.

- Rotary Engraving: Utilizes a spinning cutting tool to carve text and graphics into the plastic. Rotary engraving is suitable for thicker plates or when a deeper etch is desired.

- Screen Printing: Applies vibrant, multi-color graphics and text to the plate surface, ideal for branding or full-color logos.

- Hot Stamping: Imprints metallic or colored foils onto the plate using heat and pressure, delivering a premium look for executive nameplates or awards.

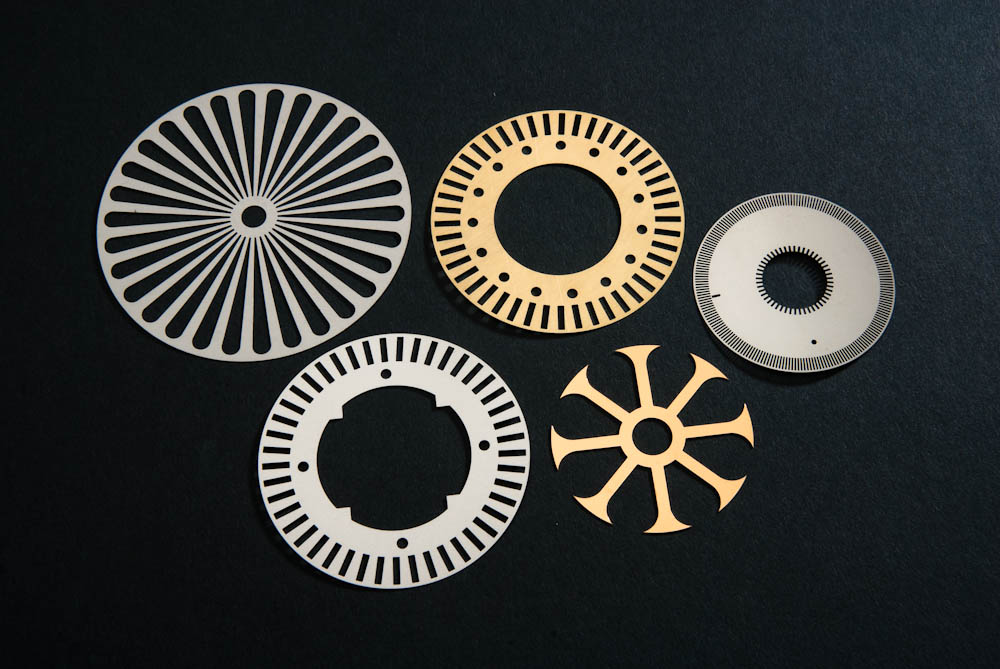

- Chemical Etching: Involves masking and selectively removing layers of plastic to create detailed designs, often used for specialty or decorative nameplates.

- Injection Molding: For high-volume applications, custom-shaped plastic nameplates can be produced in large quantities with complex contours and integrated fastening features.

Key Decision Factors When Selecting Plastic Nameplates

Not sure which plastic nameplate is best for your project or facility? Consider these important factors to guide your decision-making process:

- Intended Use: Will the nameplate be used indoors or outdoors? For temporary events or permanent installations?

- Environmental Conditions: Exposure to sunlight, chemicals, abrasion, or moisture will influence material and adhesive selection.

- Customization Requirements: Do you need variable data, such as sequential numbering, barcodes, or personalized names?

- Branding and Aesthetics: Does your nameplate need to match corporate branding, color schemes, or architectural styles?

- Budget and Quantity: Consider the cost-effectiveness of different materials and processes for single orders versus bulk purchases.

- Installation Method: Determine whether adhesive backing, screw mounting, or magnetic attachment is most appropriate for your surface and application.

Benefits of Custom Plastic Nameplates

Custom plastic nameplates provide a multitude of advantages for organizations focused on safety, efficiency, and brand image. Some key benefits include:

- Enhanced Professionalism: Well-designed nameplates deliver a polished, organized look that instills confidence in visitors and clients.

- Improved Wayfinding and Safety: Clear, legible signage streamlines traffic flow, reduces confusion, and supports compliance with safety regulations.

- Brand Consistency: Custom color, logos, and fonts reinforce your business identity across all signage and identification materials.

- Fast Turnaround: Plastic nameplates can be manufactured and shipped quickly, making them an excellent choice for last-minute requirements or rapid rebranding efforts.

- Eco-Friendly Options: Many manufacturers now offer recyclable or biodegradable plastic materials, supporting sustainability initiatives.

Frequently Asked Questions About Plastic Nameplates

- What is the best plastic for outdoor nameplates? Polycarbonate and UV-stabilized acrylic offer superior resistance to weathering and sunlight, ensuring long-lasting performance outdoors.

- Can plastic nameplates be customized with logos or graphics? Yes, advanced engraving and printing technologies allow for the inclusion of detailed logos, multi-color designs, barcodes, and QR codes.

- How are plastic nameplates installed? Depending on the application, they can be mounted using adhesives, screws, double-sided tape, magnetic strips, or Velcro fasteners.

- What are typical lead times for custom plastic nameplates? Production times vary by manufacturer and order size, but most standard orders ship within 3-7 business days.

- Are plastic nameplates suitable for high-temperature environments? Certain plastics, such as polycarbonate and specific engineering-grade polymers, can withstand elevated temperatures. Consult your supplier for recommendations.

How to Order Plastic Nameplates

Ready to order custom plastic nameplates for your organization? Follow these steps to ensure you get the perfect product for your needs:

- Define Your Application: Identify where and how the nameplates will be used (e.g., employee desks, room signage, equipment labels).

- Select Material and Finish: Choose the plastic type, thickness, and color that best fits your usage and branding requirements.

- Design Your Nameplate: Work with your supplier or use online design tools to specify text, logos, fonts, and layout.

- Choose Mounting Options: Decide how the nameplates should be attached—adhesive backing, screw holes, or magnetized strips.

- Request a Quote: Submit your specifications and quantity needed to obtain pricing and lead times from reputable manufacturers.

- Review and Approve Proofs: Carefully check digital or physical proofs to ensure accuracy before production begins.

- Place Your Order: Confirm your order and anticipated delivery date. Track your shipment for timely installation.

Tips for Maximizing the Value of Plastic Nameplates

- Opt for Layered Engraving Materials: Dual-layer plastics enhance contrast and readability, especially in low-light or high-traffic areas.

- Incorporate Braille or Tactile Features: Meet ADA compliance and improve accessibility for visually impaired users by adding raised lettering or braille.

- Specify UV-Resistant Inks and Materials: For outdoor or sun-exposed installations, UV-stabilized plastics and inks prevent fading and degradation.

- Standardize Designs Across Locations: Maintain a cohesive look and simplify future reordering by establishing company-wide design templates.

- Request Samples: Ask suppliers for sample nameplates to evaluate material quality, engraving clarity, and color accuracy before placing a large order.

Industry Use Cases: How Sectors Leverage Plastic Nameplates

Plastic nameplates are indispensable across a range of industries, each with unique requirements and design preferences. Below are some specific industry use cases to help you envision the best solutions for your organization:

- Corporate Offices: Clearly marked workspaces, meeting rooms, and reception areas enhance professionalism and organization.

- Healthcare Facilities: Durable, easily sanitized nameplates for patient rooms, nurse stations, and medical equipment support infection control and patient safety.

- Educational Institutions: Classrooms, labs, and administrative offices benefit from clear, color-coded signage for students, staff, and visitors.

- Industrial Plants: Machinery labeling, safety instructions, and asset management tags withstand harsh environments and promote operational efficiency.

- Retail and Hospitality: Branded nameplates on display cases, checkout counters, or guest rooms reinforce brand identity and improve customer experience.

- Government and Public Buildings: Wayfinding and regulatory signage ensure accessibility and compliance with local codes and ADA standards.

- Events and Conferences: Custom nametags and directional signage streamline attendee management and create a polished, professional atmosphere.

Comparing Plastic vs. Metal and Wood Nameplates

Curious about how plastic nameplates stack up against traditional materials? Here’s a breakdown to help you weigh the pros and cons:

| Feature | Plastic | Metal | Wood |

|---|---|---|---|

| Cost | Low | Medium-High | Medium |

| Durability | Excellent (especially for indoor/outdoor use) | Very High (but may tarnish/rust) | Moderate (susceptible to moisture) |

| Customization | High (colors, shapes, finishes) | Medium (limited finishes) | Low-Medium (natural grain limits) |

| Maintenance | Low | Medium-High | High |

| Weight | Light | Medium-Heavy | Medium |

| Eco-Friendliness | Available (with recyclable/biodegradable options) | Recyclable | Biodegradable |

How to Get the Most Out of Your Plastic Nameplate Investment

Strategically selecting and designing your plastic nameplates can maximize their impact and longevity. Consider partnering with experienced nameplate manufacturers who offer design consultation, material selection guidance, and rapid prototyping. Always request digital proofs and, if possible, physical samples prior to approval. Regularly review and update signage to reflect organizational changes, ensuring your nameplates remain accurate and relevant.

Start Your Plastic Nameplate Project Today

Ready to enhance your organization’s identification and signage systems? Whether you’re searching for cost-effective door nameplates, professional desk nameplates, or custom-engraved solutions for specialized equipment, plastic nameplates offer a winning combination of value, versatility, and performance. Get started by exploring available door nameplate options or connect with leading nameplate manufacturers to design the perfect solution for your needs.

Related Search Prompts

- What are the best materials for custom nameplates in office environments?

- How do I choose between plastic, metal, and wood nameplates for my business?

- Where can I order bulk plastic nameplates for my facility?

- What engraving options are available for plastic nameplates?

- Which plastic nameplate materials are most resistant to sunlight and chemicals?

- How do I design ADA-compliant plastic signage for my building?

- What are the benefits of using custom nameplates for brand recognition?

- How fast can I receive custom-engraved plastic nameplates for my project?

- Are there eco-friendly plastic nameplate options available?

Still have questions? Reach out to a reputable plastic nameplate manufacturer for expert advice, product samples, and a custom quote tailored to your unique requirements.

Laser Cutting

Laser Cutting Lasers

Lasers Marking Machinery

Marking Machinery Metal Etching

Metal Etching Name Plates

Name Plates Labeling Equipment

Labeling Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services