Nameplates are tools of identification, usually fashioned in the form of signs or labels engraved or otherwise adorned with information. They are found all around, from office doors, to desks, to bridges. Read More…

At STRYKER, we take pride in designing and manufacturing precision name plates that serve as both identification and branding tools for a wide range of industrial and commercial applications. We understand that name plates are more than simple labels—they represent a company’s identity, quality, and attention to detail.

We are a manufacturer of identification products for original equipment manufacturer’s and utilities. For 75 years we have made pole tags, cable markers, data plates, safety signs and all things identification. Tech Products, Inc. provides the most durable products in our industries with brand names like EVERLAST, Tech-3D, FASTTAG, and TechBrite. We are also a service company – an information ...

At Nameplate & Panel Technology, we are proud to be a leading provider of high-quality nameplates and panel solutions that meet the diverse needs of businesses across various industries. With decades of experience and a commitment to innovation, we have earned a reputation for excellence in the field of custom identification and labeling.

JN White is an ISO 9001:2015 and ITAR-certified manufacturer of name plates, graphic overlays, and custom labels. We nimbly handle projects big and small and have the uncommon ability to translate what our customers need into high-quality, high-precision outcomes. Our team's goal is to bring you the best through our dedication to quality and our constant pursuit of the latest technology. contact...

More Name Plate Manufacturers

Nameplates and nametags are both integral components of personal and professional identification, yet they serve distinctly different functions in various environments. Nameplates are typically installed on permanent or semi-permanent surfaces—such as office walls, machinery, vehicles, doors, or statues—to display essential information or branding. In contrast, nametags are worn on clothing, primarily in professional or event settings, to facilitate introductions and promote communication. Nametags are rarely inscribed permanently, often relying on temporary or reusable materials. Furthermore, nameplates differ from name plaques, which are larger, designed for more comprehensive information, and often used for awards, dedications, or memorials.

Applications of Nameplates

Nameplates serve a vast range of industrial, commercial, institutional, and personal applications. Their core function is to convey information swiftly and succinctly, ensuring viewers receive critical details at a glance. In office and professional environments, nameplates identify office occupants, specify job titles, and label cubicles or desks. They may also guide visitors by indicating the location of emergency exits, restrooms, meeting rooms, and other key facilities within a building or campus. For wayfinding and navigation, directional nameplates are essential in large buildings, hospitals, schools, or outdoor venues.

In museum and gallery settings, professional nameplates offer valuable context for artwork and sculptures, listing titles, artists, materials, and origins—thereby enriching visitor experiences and supporting educational objectives. Personal nameplates are widely used for indicating ownership on items like luggage, briefcases, trunks, electronics, and tools. In educational or recognition contexts, they are affixed to trophies, plaques, or certificates, celebrating achievements and commemorating milestones.

Industrial nameplates play a crucial safety and operational role in manufacturing facilities, warehouses, and plants. Here, nameplates may provide machine instructions, equipment warnings, compliance information, part numbers, and serial numbers. Regulatory agencies often require these for traceability, maintenance, and safety compliance. In harsh environments—such as chemical plants, marine vessels, or outdoor installations—durable nameplates made from robust materials ensure legibility and resilience under extreme conditions.

Looking for a specific use case? What are the best nameplate options for outdoor or industrial environments? Explore our buyer’s guide to durable and weather-resistant nameplates for heavy-duty applications.

Nameplate Designs

Modern nameplate manufacturers employ a diverse array of fabrication and marking techniques to achieve the desired appearance, durability, and functionality. The method chosen depends on the intended application, material, environment, and required level of detail.

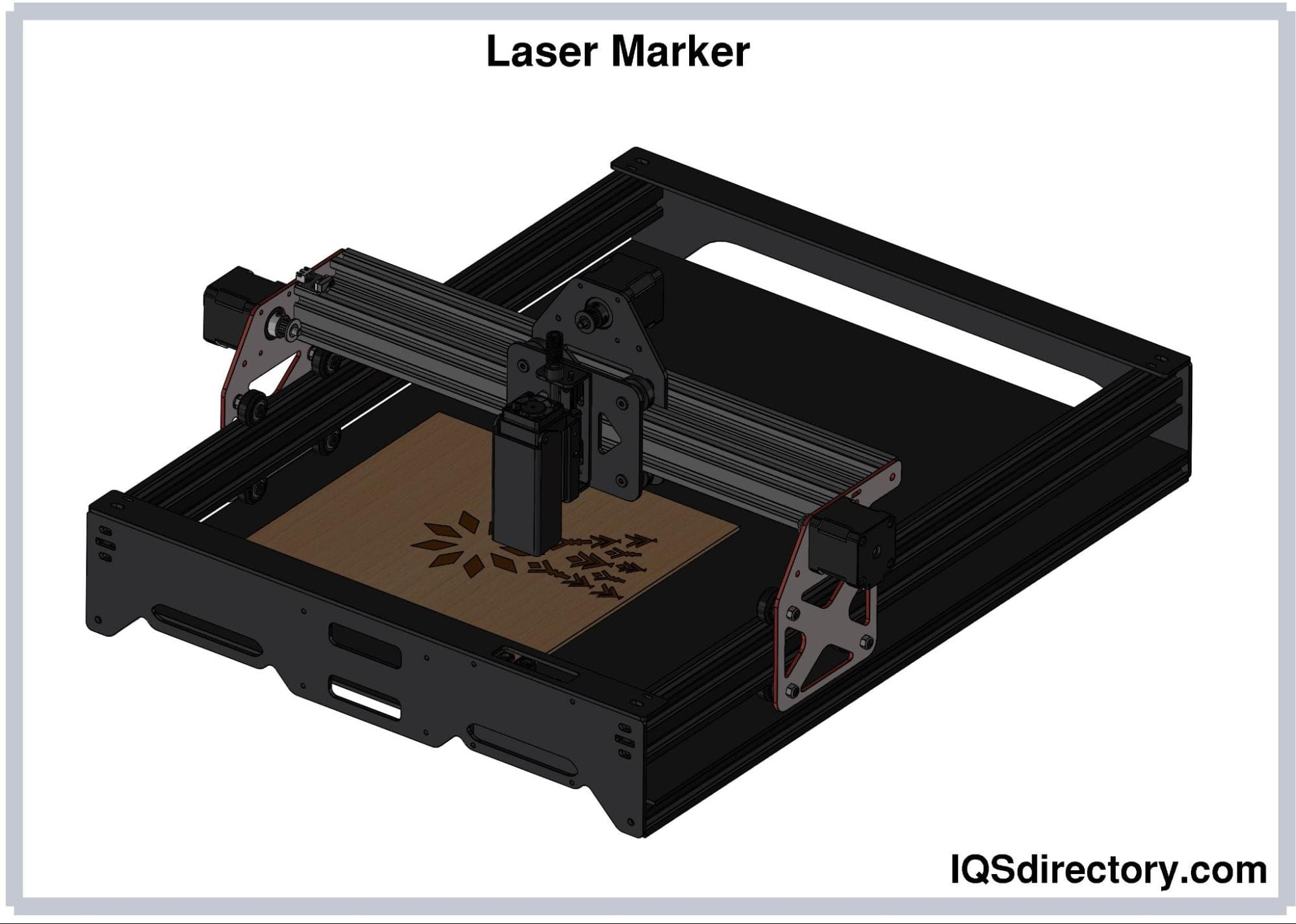

- Laser Engraving: Laser engraving uses a focused beam of light to etch designs, text, or graphics into the nameplate surface. This method offers exceptional precision and is ideal for intricate logos, small fonts, barcodes, or data matrices. Laser-engraved nameplates are highly durable, making them suitable for industrial, laboratory, or commercial settings where abrasion resistance and legibility are critical.

- Mechanical Engraving: Utilizing a rotary engraving tool or CNC machine, this technique physically carves out the design. Mechanical engraving is valued for its permanence and clarity—especially in metal nameplates for machinery, control panels, and asset tags.

- Screen Printing: This process applies ink through a mesh screen and stencil, allowing for vibrant color finishes and large-scale production. Screen printed nameplates are common for branding, product identification, and promotional materials where color accuracy and visual impact are important.

- Sub-surface Printing: In this advanced process, inks or dyes are applied beneath a transparent substrate (such as polycarbonate or acrylic). The result is a nameplate label protected from environmental exposure, chemicals, and abrasion—ideal for medical equipment, outdoor signage, and marine applications.

- Hot Stamping: A dry imprinting process where heat and pressure transfer metallic foils or pigmented films onto the surface. Hot stamping is commonly used for serial numbers, decorative accents, or logos on metal and plastic nameplates.

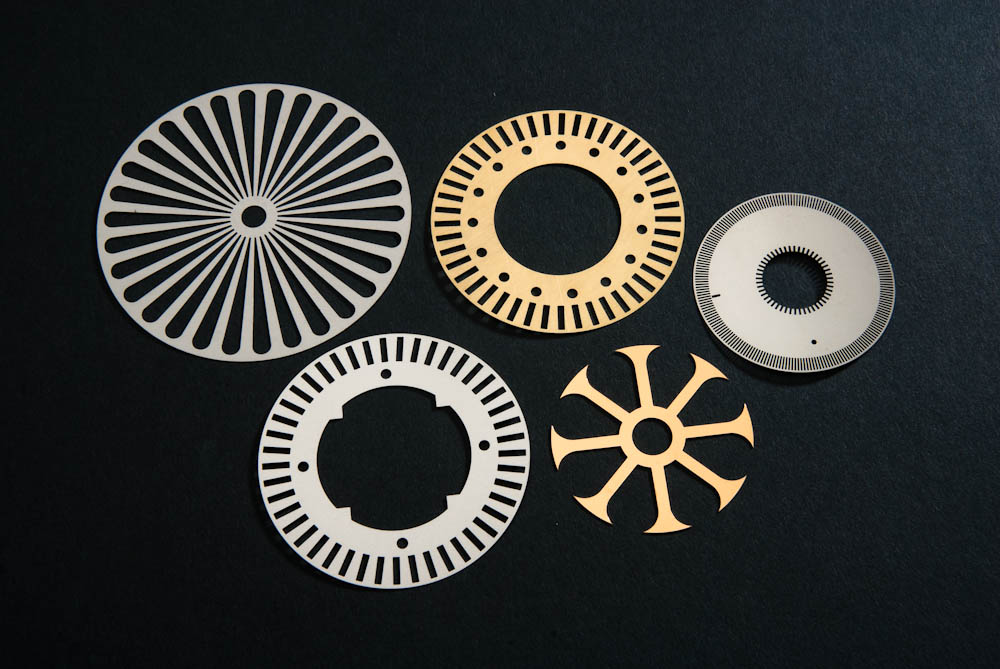

- Chemical Etching: By masking and exposing specific areas to etchants, chemical etching produces finely detailed graphics, text, and patterns on metals such as stainless steel, aluminum, and brass. Chemically etched nameplates provide exceptional detail and are standard for control panels, valve tags, and compliance labeling.

- Embossing/Debossing: Using matched male and female dies, manufacturers create raised (embossed) or recessed (debossed) designs, adding tactile and visual interest. Embossed nameplates are often used for branding, corporate signage, and luxury packaging.

- Photo Anodizing (MetalPhoto®): A proprietary process for embedding graphics and text into the anodized layer of aluminum sheets. MetalPhoto® nameplates are known for their photographic resolution, UV stability, and resistance to chemicals, making them a preferred choice for military, aerospace, and industrial asset identification.

Curious about which marking method fits your application? How do I choose the best nameplate marking technique for my needs? See our comprehensive guide to engraving and printing methods.

Nameplate Materials

Material selection is a critical decision in nameplate manufacturing, impacting appearance, durability, cost, and compliance. The most common nameplate materials include:

- Metals: Aluminum (lightweight, corrosion-resistant, affordable), stainless steel (exceptional strength, chemical and heat resistance), brass (decorative, corrosion-resistant, used outdoors), zinc, copper, and bronze (luxury or executive applications).

- Plastics: Rigid PVC (cost-effective, weather-resistant), vinyl (flexible, easy to print), polycarbonate (impact-resistant, clear), acrylic (glossy, UV stable), Mylar® (durable, used for overlays).

- Composites: MetalPhoto® aluminum (photo-anodized for extreme durability), laminated plastics for layered strength and color options.

- Wood: Used for decorative nameplates, children’s rooms, and offices seeking a natural or traditional look.

Selecting the right material depends on the intended environment (indoor vs. outdoor), exposure to chemicals or moisture, desired lifespan, weight requirements, and aesthetic preferences. For industrial and outdoor use, metals like stainless steel or anodized aluminum are preferred for their longevity and resistance to harsh conditions. In contrast, office or retail applications may prioritize plastics or wood for design flexibility and affordability.

Not sure which material suits your needs? Learn more about choosing the ideal nameplate substrate for your application.

Customizing Nameplates

Customization is at the heart of modern nameplate manufacturing. Leading nameplate suppliers collaborate closely with clients to deliver products tailored to unique requirements and branding objectives. Key factors considered during the customization process include:

- Message and Content: The text, numbers, logos, and graphics to be included, ensuring compliance with regulatory or corporate guidelines.

- Design and Aesthetics: Font style, size, color, and layout, as well as any specific branding elements.

- Shape and Dimensions: Custom shapes (rectangular, oval, circular, or bespoke) and sizes tailored to the mounting surface.

- Material and Finish: Selection of substrates and finishes such as brushed, matte, gloss, anodized, or powder-coated.

- Mounting Options: Pre-drilled holes, adhesive backing, magnetic mounts, or custom holders and frames.

- Environmental Requirements: UV resistance, temperature tolerances, moisture and chemical resistance for demanding settings.

- Volume and Budget: Production run size, cost considerations, and turnaround time.

Whether you need a single commemorative nameplate or thousands of serialized asset tags, nameplate manufacturers can accommodate a vast range of custom orders. The design process often involves digital proofs, prototype sampling, and iterative revisions to ensure the final product meets all specifications.

Ready to start a project? Request a quote from top-rated custom nameplate manufacturers today.

Types of Nameplates

The versatility of nameplates is reflected in the wide array of types available, each engineered for specific use cases and environments:

- Office Nameplates: Used to identify employees, job titles, and office locations. Available as desk nameplates, wall nameplates, or door nameplates. Also includes conference room signs, restroom signs, and directional signage.

- Industrial Nameplates: Essential for labeling equipment, machines, tools, and workstations in manufacturing, logistics, and laboratory environments. Known for durability, often constructed from stainless steel or anodized aluminum.

- Equipment Nameplates: Display vital information such as serial numbers, model numbers, safety instructions, load limits, and regulatory compliance data on machinery and vehicles.

- Graphic Overlay Nameplates: Feature embossing, clear windows, selective texturing, and are used on membrane switches, control panels, and keypads. Resistant to chemicals and abrasion, these overlays are crucial for electronics and medical devices.

- Digital Nameplates: Connect physical products to digital resources via QR codes, NFC tags, or barcodes. Enable users to access manuals, support, or warranty information by scanning the code—ideal for smart products and IoT devices.

- Number Plates / License Plates: Serve as unique vehicle identifiers, crafted from plastic or metal for compliance and durability. Used for cars, trucks, motorcycles, and trailers.

- Gold and Luxury Nameplates: High-end, elegant options made from precious metals for executive offices, museums, institutions, and commemorative displays.

- Wooden Nameplates: Popular for homes, children’s rooms, or decorative purposes. Customizable in shapes, colors, and designs—great for personalized gifts or themed decor.

- Bronze Nameplates: Exude prestige, often found on executive desks, historic buildings, and monuments. Chosen for their substantial weight and classic appearance.

- Aluminum Nameplates: Lightweight, corrosion-resistant, and cost-effective; ideal for consumer products, electronics, and general equipment labeling.

- Plastic Nameplates: Affordable, low-maintenance, and suitable for both indoor and outdoor applications where budget is a primary concern.

- Brass Nameplates: Attractive and weather-resistant, often used for building exteriors, statues, and architectural signage. Many are treated with protective coatings to prevent tarnishing.

Want a quick comparison? Which nameplate type is best for my specific application? Check our interactive nameplate selection tool for tailored recommendations.

Benefits and Advantages of Nameplates

The strategic use of nameplates delivers numerous benefits across industries:

- Professional Appearance: Enhances branding, professionalism, and organizational image.

- Efficient Identification: Facilitates quick recognition of personnel, equipment, and locations, improving workflow and safety.

- Compliance and Traceability: Ensures adherence to industry regulations for product labeling, asset management, and quality control.

- Durability: High-quality nameplates withstand harsh environments, reducing maintenance and replacement costs.

- Customization: Tailored design options allow for alignment with corporate branding, messaging, and specific use cases.

- Easy Installation and Updates: Flexible mounting methods and interchangeable inserts enable fast deployment and information updates.

Nameplate manufacturers offer a range of accessories to enhance usability and display options, such as wall mount adhesives for seamless application, decorative hanging chains, pins, hooks, hangers, nameplate frames, and snap-on label holders. These options help businesses achieve the optimal balance of function and aesthetics in any environment.

Looking to maximize ROI? Discover cost-effective nameplate solutions for your industry.

How to Install Nameplates

Proper installation is key to nameplate longevity and effectiveness. The main mounting techniques are:

- Mechanical Fasteners: Involves drilling holes in the nameplate and securing it with screws, rivets, pins, or nails. Provides a robust, permanent hold—ideal for machinery, equipment, or outdoor signage. Many nameplates come with pre-drilled holes for convenience.

- Adhesives: Industrial-grade adhesives offer a clean, fast, and secure installation without the need for drilling. It is vital to select an adhesive compatible with both the nameplate material and the mounting surface, especially for outdoor or high-moisture environments.

- Structural Supports: Nameplate holders, frames, or stands—often made from plastic, wood, or metal—provide an elevated, professional display for office desks, lobbies, or public spaces. These are particularly useful for heavy or decorative nameplates.

Considering a DIY installation? What are the best practices for mounting nameplates securely? Read our installation and maintenance guide.

Industry Standards and Compliance

Adhering to industry standards is essential for certain types of nameplates, especially in regulated sectors. While general office and decorative nameplates have few restrictions, industrial and equipment nameplates must comply with strict guidelines to ensure safety, traceability, and durability.

- NEMA Standards: In the United States, electric motor nameplates must follow National Electrical Manufacturers Association (NEMA) requirements, displaying critical data such as manufacturer type, voltage, frequency, RPM, temperature rise, insulation system class, current, service factor, frame size, and efficiency.

- UL, CSA, and ISO: For electrical, electronic, and safety-related applications, nameplates may require certification from Underwriters Laboratories (UL), Canadian Standards Association (CSA), or compliance with ISO standards for labeling and identification.

- Environmental and Print Durability: Certain industries require nameplates to pass tests for UV stability, salt spray resistance, abrasion, and chemical exposure. MetalPhoto® and laser-etched stainless steel are popular choices for such demanding environments.

Need to meet compliance and certification requirements? Consult our buyers’ checklist for industrial nameplate standards.

How to Choose the Right Nameplate Manufacturer

Selecting an experienced, reputable nameplate manufacturer is pivotal to ensuring product quality, on-time delivery, and compliance with your specifications. Here’s how to make an informed decision:

- Define Your Requirements: Prepare a detailed list of your needs—including application, quantity, budget, material, design, and compliance standards.

- Evaluate Supplier Expertise: Review manufacturer credentials, portfolio, and experience serving your industry or similar applications.

- Request Samples: Examine material and print quality firsthand. Reliable manufacturers should provide prototypes or sample packs.

- Check Certifications: Ensure suppliers are certified for processes such as ISO, UL, or other industry-specific standards.

- Compare Quotes and Lead Times: Balance cost, quality, and turnaround to find the best fit for your project timeline and budget.

- Ask About After-Sales Support: Inquire about warranties, reordering, and customer service responsiveness.

You can find trustworthy nameplate manufacturers by exploring the profiles on this page, which are interspersed with our informative content and expert recommendations. For a streamlined search, create a comprehensive specification sheet before reaching out to suppliers.

Ready to connect with the best? Browse our curated directory of leading nameplate manufacturers to get started.

Frequently Asked Questions About Nameplates

- What are the most durable nameplate materials for outdoor use? Stainless steel, anodized aluminum, and MetalPhoto® aluminum offer exceptional weather resistance and longevity.

- Can nameplates be customized with company logos and QR codes? Yes, most suppliers offer full customization, including branding elements, serial numbers, and digital codes.

- How do I choose between plastic and metal nameplates? Consider application, exposure, budget, and design needs—metal for durability, plastic for cost and flexibility.

- What are the latest trends in nameplate design? Smart nameplates with QR/NFC integration, sustainable/recyclable materials, and laser-etched graphics are growing in popularity.

- How long does production take for custom nameplates? Lead times vary by order size and complexity, but most suppliers offer expedited service for urgent needs.

Have more questions? Visit our nameplate knowledge base or contact our experts for personalized guidance.

Conclusion: Maximizing Value with the Right Nameplate Solution

Whether you’re outfitting an office building, labeling industrial machinery, enhancing product branding, or commemorating achievements, nameplates play an essential role in identification, safety, and communication. By understanding the different types, materials, design methods, and compliance requirements, you can make informed decisions that align with your goals and budget.

For optimal results, partner with a nameplate manufacturer that offers expertise, advanced customization, and responsive service. Use the resources and profiles on this page to start your research and connect with industry leaders who can bring your project to life.

Take the next step: Explore our complete directory of nameplate manufacturers, request a quote, or consult our guides to ensure you get the perfect solution for your needs.

Laser Cutting

Laser Cutting Lasers

Lasers Marking Machinery

Marking Machinery Metal Etching

Metal Etching Name Plates

Name Plates Labeling Equipment

Labeling Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services