More Name Plate Manufacturers

Nameplates and nametags serve distinct functions. Nameplates are generally installed on surfaces such as walls, vehicles, or statues, whereas nametags are worn on clothing. Nametags are rarely inscribed. Furthermore, nameplates are different from name plaques, which are larger and intended to convey more comprehensive information.

Applications of Nameplates

Primarily, customers utilize nameplate products to convey information swiftly and succinctly rather than displaying extensive details. In office and professional settings, nameplates often provide crucial information such as the contents of desks, the location of emergency exits, and navigational directions within a building or outdoor area. Additionally, some professional nameplates offer insightful details about artwork and sculptures, including authorship, titles, and origins, enriching the observer’s understanding and appreciation.

Personal nameplates serve a distinct purpose, indicating ownership of items such as chests, suitcases, briefcases, and trunks. They also commemorate achievements by displaying the name and title of award recipients on trophies, plaques, or memorials, thus preserving significant moments and honoring individuals. In industrial contexts, nameplates are essential for labeling products, providing machinery instructions, and issuing equipment warnings. These nameplates play a vital role in ensuring safety and operational efficiency, offering clear and immediate information in environments where precision and clarity are paramount.

Nameplate Designs

Manufacturers have a diverse array of techniques at their disposal for adorning nameplate products with labels, each offering unique benefits and suited to different applications.

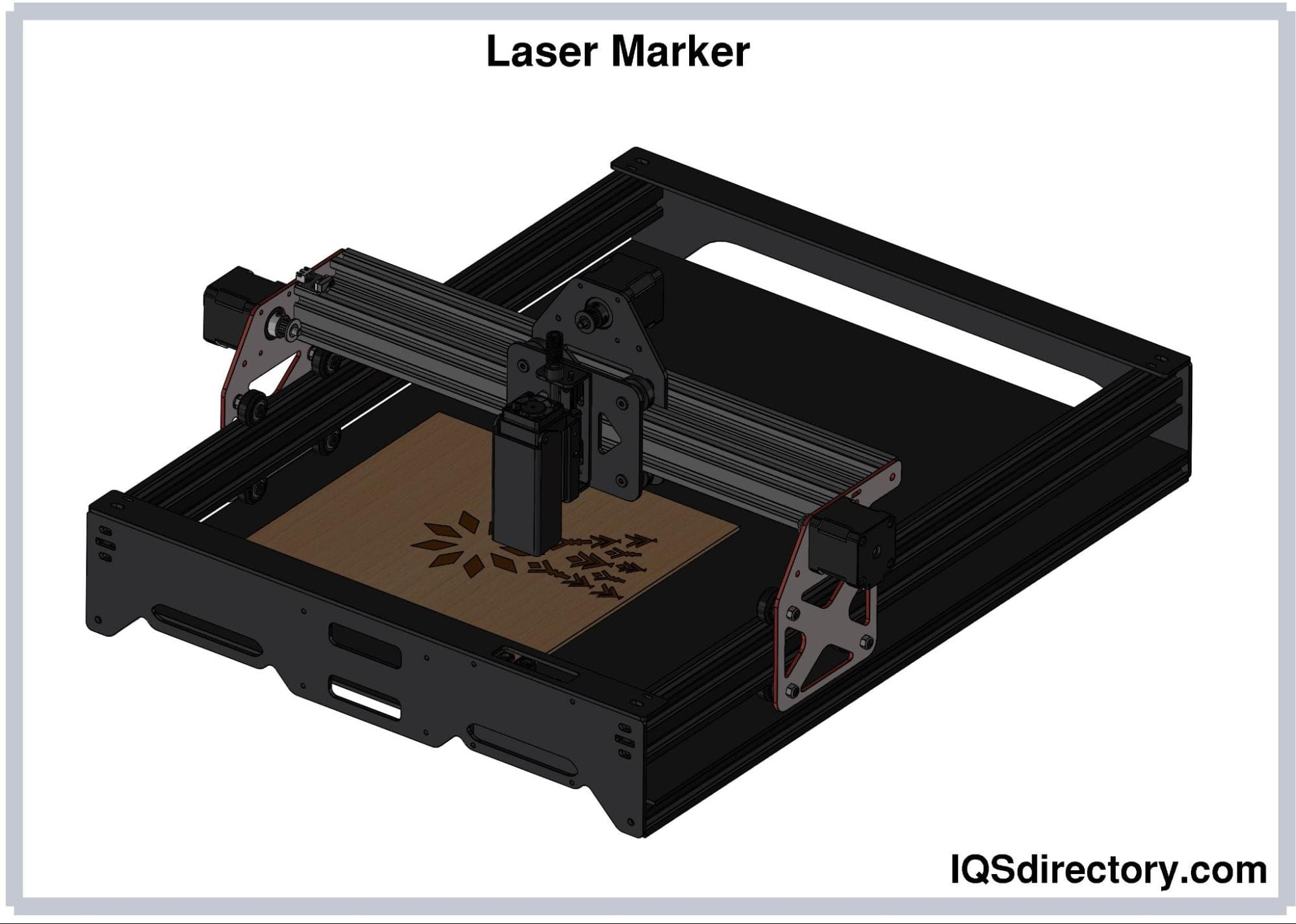

Laser engraving is one of the most precise and intricate methods, where a laser beam cuts into the nameplate to create detailed designs. This method is ideal when the utmost accuracy is required.

Mechanical engraving, on the other hand, utilizes a rotary tool to carve labels into the nameplate. This approach is known for its durability and clarity, making it a popular choice for many industrial applications.

Screen printing is a more involved process. It begins with applying a photogenic stencil to a piece of tightly stretched, porous polyester or another mesh. Enamel colors are then forced through this mesh. The stencil’s role is to block the ink from touching the areas of the mesh it covers, allowing only the desired design to be printed onto the nameplate.

Sub-surface printing is a specialized technique where manufacturers print beneath the surface or on the back of a substrate. This method is particularly effective for creating nameplate labels that must withstand harsh environmental conditions, such as UV exposure, salt air, and abrasive elements or solvents. By positioning the print below the surface, it is well-protected from external damage, ensuring longevity and durability.

Hot stamping is a dry printing process in which manufacturers press dry paint or foil onto a metal or plastic substrate. This method relies on high heat and a die, made of metal or rubber, to transfer the paint or foil onto the substrate. The die presses down on the product, with the paint or foil placed between them, imprinting the design onto the surface. Hot stamping is frequently used to add serial numbers to nameplates, providing a clear and lasting mark.

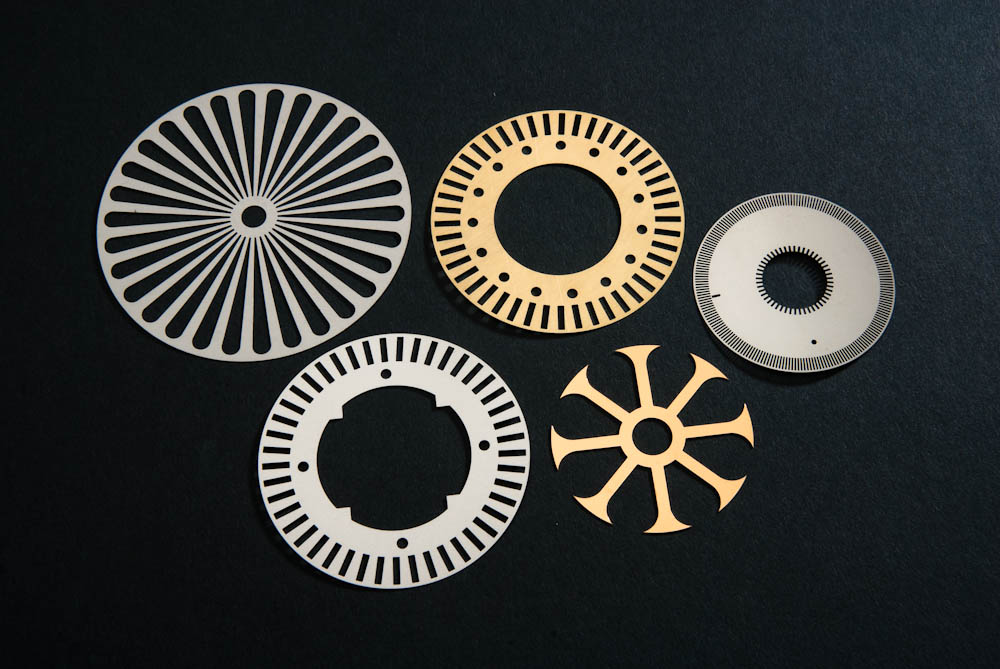

Chemical etching is a precise technique used to engrave metal nameplates made of materials such as stainless steel, aluminum, or brass. The process begins with manufacturers shielding specific areas of the nameplate material with an acid-resistant coating. The exposed areas are then subjected to a corrosive material, which engraves the metal according to a stencil design. This method allows for intricate designs to be etched into the metal without damaging the protected areas, resulting in a detailed and durable nameplate.

Embossing differs from other methods by using heat and pressure to shape the metal plate as it passes through both a female and a male roller die. Each die is crafted with the desired pattern, and the application of pressure creates a raised or recessed design on the nameplate. This technique adds a tactile dimension to the nameplate, enhancing its visual appeal and functionality.

Photo anodizing utilizes specialized aluminum sheets to produce photo-quality images and text. This method is ideal for creating high-resolution, durable nameplates that require detailed graphics or fine lettering. By combining the durability of anodized aluminum with the clarity of photographic printing, photo anodizing ensures that nameplates remain legible and aesthetically pleasing even in challenging environments.

Nameplate Materials

Nameplates, versatile in their composition, are crafted from an array of materials, with each industry favoring different options based on specific needs and aesthetics. In professional office settings, nameplates are often fashioned from plastic, wood, or various metals, including aluminum, aluminum alloys, stainless steel, brass, zinc, and copper. Additionally, manufacturers may employ materials such as rigid PVC, vinyls, foils, Mylar®, and MetalPhoto® to create nameplates that meet unique requirements and preferences.

Customizing Nameplates

When crafting their products, nameplate manufacturers meticulously consider various factors to ensure the nameplate aligns perfectly with your needs and preferences. They contemplate the specific message you want the nameplate to convey, the desired aesthetic and design, the intended placement, the quantity required, and any relevant standard requirements that must be met.

With these considerations in mind, nameplate suppliers are equipped to offer a vast array of design possibilities. This includes choices in size, material, font, mounting style, and weight. The creation of custom nameplates is a straightforward process, as every nameplate inherently involves a degree of customization, tailored to display personalized messages, labels, or instructions.

Types of Nameplates

Office nameplates distinguish the inhabitants and roles within various offices and desks, generally showcasing one or two lines of detail, often a name and position. These nameplates come in various forms, including desk nameplates, wall nameplates, and door nameplates, each crafted to fit their respective locations. On a broader scale, office signs fulfill the role of larger nameplates, identifying different areas within a building, such as waiting rooms and restrooms, providing instructions to employees, customers, or visitors, and offering navigational guidance. Unlike nameplates, office signs are predominantly affixed to walls rather than placed on desks, although those attached to doors are also known as door signs or door nameplates.

Industrial nameplates, used to label equipment and workpieces in industrial facilities, are typically made from durable materials such as stainless steel. These nameplates, often referred to as equipment nameplates when attached to machinery, are especially valued in outdoor or demanding environments due to their resilience.

Graphic overlay nameplates, characterized by embossing, transparent window displays, and selective texturing, are commonly used for LEDs, windows, switches, or control panels. They are typically resistant to corrosion and chemicals, making them a durable choice for these applications.

Digital nameplates go beyond providing visual details by linking to digital resources such as customer support and product pages. They often feature serial numbers, tags, and a range of alphanumeric codes, which users can access by scanning the nameplate. This approach enhances the functionality of product nameplates without the need to add more physical information. Chemical engraving is commonly used by manufacturers, as it ensures that the information remains readable and scannable over time.

Number plates, commonly known as license plates, are crafted from plastic or metal to serve as unique identifiers for vehicles. These essential nameplates ensure that each vehicle can be easily recognized and traced.

Among nameplates, those made from gold stand out as the most luxurious and expensive. These prestigious plates find their place in offices and esteemed institutions, where they are often mounted on paintings, display cases, plaques, and doors. Such settings include museums, universities, cathedrals, and the offices of high-profile businesses, where the elegance of gold adds a touch of grandeur and distinction.

Wooden nameplates, as their name suggests, are crafted from wood. These nameplates are particularly popular for adorning the doors of children’s playrooms or bedrooms. Often personalized with a child’s name or designed in whimsical shapes like animals, wooden nameplates are favored for their safety, affordability, and customizability. Parents and children alike can enjoy painting these wooden plates, making them a charming and creative addition to a child’s space.

Bronze nameplates, often seen gracing the desks of office executives, represent the pinnacle of office nameplate elegance and cost. Their rich hue and substantial weight convey a sense of prestige and permanence, making them a symbol of authority within the corporate environment.

In contrast, aluminum nameplates stand out for their affordability and widespread use. Their lightweight nature and resistance to corrosion make them a practical choice for a variety of applications. From providing essential operational instructions on consumer products like lawn mowers and washing machines to identifying offices within large buildings, aluminum nameplates offer a versatile and durable solution.

Plastic nameplates, even more economical than their aluminum counterparts, are favored for their minimal maintenance requirements. Despite their lower cost, they effectively serve a wide range of identification needs, providing a cost-effective and hassle-free option for businesses and organizations.

Brass nameplates, crafted for outdoor applications like building fronts or statues, are favored for their aesthetic appeal. Manufacturers often coat these nameplates with weather-resistant chemicals to prevent tarnishing, ensuring their durability and maintaining their elegant appearance.

Advantages of Nameplates

Nameplate manufacturers provide a variety of essential accessories designed to enhance the functionality and presentation of their main products. These accessories primarily focus on the physical support and secure attachment of the nameplates. Among the options available are wall mount adhesives, which ensure a firm bond to surfaces, and wall hanging chains that offer a stylish suspension method. Pins, hooks, and hangers provide versatile mounting solutions, while nameplate frames and holders add a touch of elegance and protection. Additionally, snap-on nameplate label holders and inserts offer convenient ways to update and customize information displayed on the nameplates.

Installing Nameplates

Users can mount nameplates using three primary methods: securing them with fasteners, adhering them with adhesives, or supporting them with structures. Securing nameplates with fasteners, although relatively simple, requires a detailed approach, involving drilling holes into the nameplates, positioning them at the desired location, and inserting screws, pins, nails, or other fasteners. Some nameplates conveniently come with pre-drilled holes, simplifying the process. Adhesive coatings, available at local hardware stores or from nameplate suppliers, offer an alternative solution, with the crucial need to select an adhesive that matches the environment where the nameplate will be used for a lasting bond. Structural supports, commonly crafted from plastic, wood, or metal, are particularly beneficial for heavy office and desk nameplates, ensuring they are displayed prominently and securely.

Standards

Nameplate standards are usually less stringent and detailed compared to most industrial item standards. When standards do apply to nameplates, they typically pertain to industrial or equipment nameplates, emphasizing environmental durability and print longevity. Equipment like centrifugal pumps, generators, and electric motors generally require more rigorous standards for their nameplates.

In the USA, motor nameplates must adhere to the National Electrical Manufacturers Association (NEMA) standards. NEMA mandates that motor nameplates display specific information: manufacturer type, rated voltage, rated frequency, rated full load RPM, rated temperature rise (insulation system class), full-load current, time rating, number of phases, horsepower, frame size, service factor, design letter, locked rotor code letter, and efficiency.

Things to Consider

To obtain high-quality nameplates, partnering with an experienced manufacturer is crucial. They will ensure your nameplates are either professionally crafted or whimsically designed for children, as needed. Accuracy in details and timely delivery are guaranteed.

You can find trustworthy nameplate manufacturers by exploring the profiles on this page, interspersed with our informative content. Before reviewing these profiles, we recommend creating a comprehensive specifications list. This list should outline all your requirements, from volume to budget, to streamline your search and enhance your discussions with potential suppliers.

Laser Cutting

Laser Cutting Lasers

Lasers Marking Machinery

Marking Machinery Metal Etching

Metal Etching Name Plates

Name Plates Labeling Equipment

Labeling Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services