Aluminum nameplates are made of aluminum with names, directions, or other information engraved, etched, or otherwise labeled. In manufacturing, they often display warnings, brand names, and instructions for machinery. Read More…

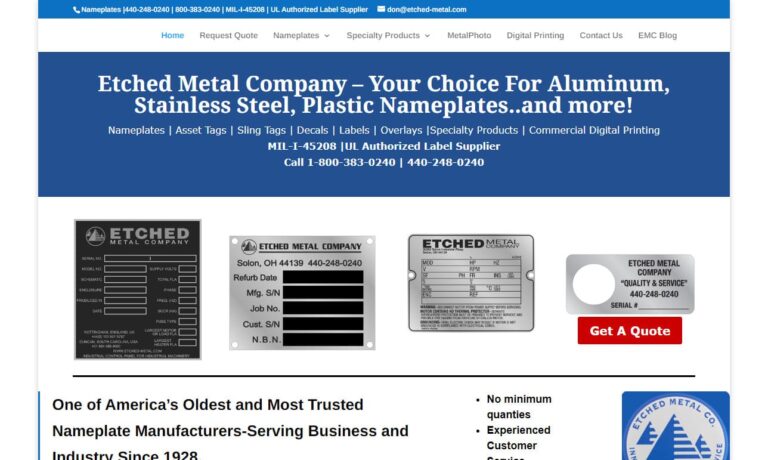

Etched Metal Company takes pride in our expertise and precision in crafting exceptional name plates. With over 80 years of collective experience, we have mastered the arts of etching, anodizing, silk screening, and digital printing to create distinctive and durable identification solutions. Our commitment to excellence is reflected in every meticulous detail, ensuring that each name plate meets...

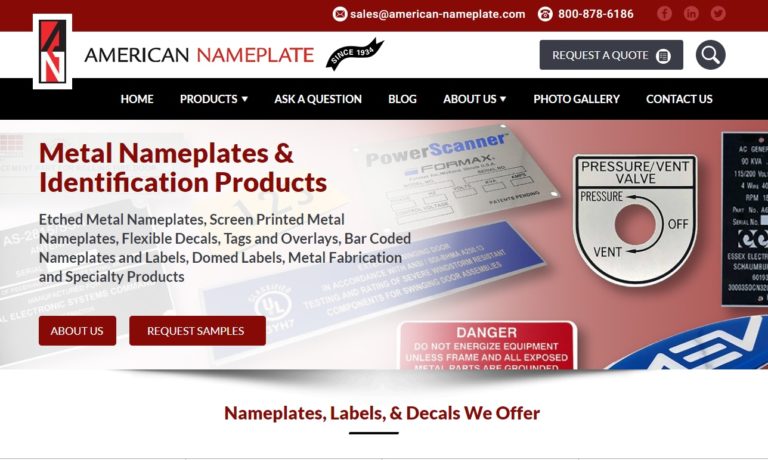

At American Nameplate, we take pride in our commitment to delivering high-quality identification solutions that meet the diverse needs of our customers. We specialize in manufacturing durable and custom name plates designed to withstand various environments and applications. Our expertise extends to creating products that meet stringent specifications for industries such as aerospace, automotive, ...

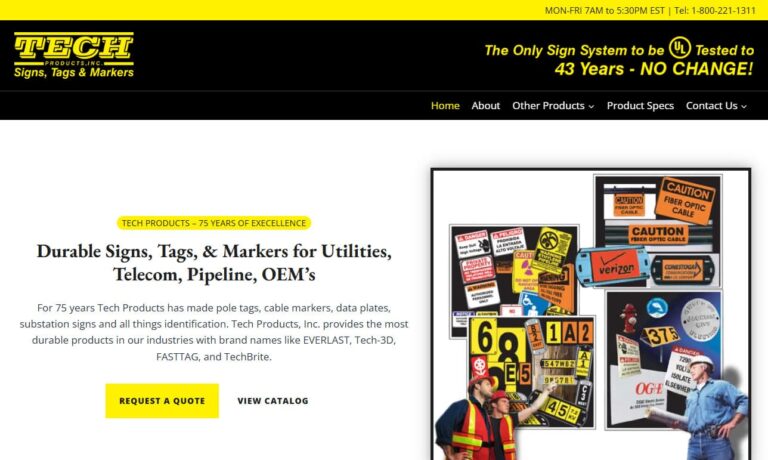

We are a manufacturer of identification products for original equipment manufacturer’s and utilities. For 75 years we have made pole tags, cable markers, data plates, safety signs and all things identification. Tech Products, Inc. provides the most durable products in our industries with brand names like EVERLAST, Tech-3D, FASTTAG, and TechBrite. We are also a service company – an information ...

Metal Marker Manufacturing has the capabilities to provide aluminum nameplates that are durable, lightweight, and strong. In business since 1923, we have experience producing aluminum nameplates for industries ranging from aerospace to military. We can also use our Metalphoto technology to develop nameplates for harsh conditions. With our USA-made products and ISO 9001 & AS910 certified quality...

At Indianapolis Badge & Nameplate Company, we specialize in creating high-quality nameplates designed to meet the diverse needs of our clients. Our team is dedicated to producing durable and visually appealing solutions, tailored to various industries and applications. From custom designs to precision manufacturing, we utilize advanced materials and processes to ensure each nameplate we deliver...

JN White is an ISO 9001:2015 and ITAR-certified manufacturer of name plates, graphic overlays, and custom labels. We nimbly handle projects big and small and have the uncommon ability to translate what our customers need into high-quality, high-precision outcomes. Our team's goal is to bring you the best through our dedication to quality and our constant pursuit of the latest technology. contact...

More Aluminum Nameplate Manufacturers

Applications of Aluminum Nameplates

In contrast to other nameplate materials like brass, copper, and gold, aluminum plates are exceptional because they are resistant to continuous exposure to extreme weather, oxidation, damage, UV rays, and other harmful effects. They’re often used on outdoor equipment that undergo inclement weather, abrasions, and collisions. Although they are frequently painted or coated to improve their look, aluminum nameplates can also be used as indoor labeling and wayfinding. They can be affixed to surfaces using adhesive or fasteners.

Nameplates are often fastened indoors instead of outdoors because many adhesives are sensitive to changing temperatures and weather conditions. Aluminum nameplates are used by and supplied to various businesses that produce consumer goods, office supplies, automobiles, and many more.

Designing and Manufacturing Aluminum Nameplates

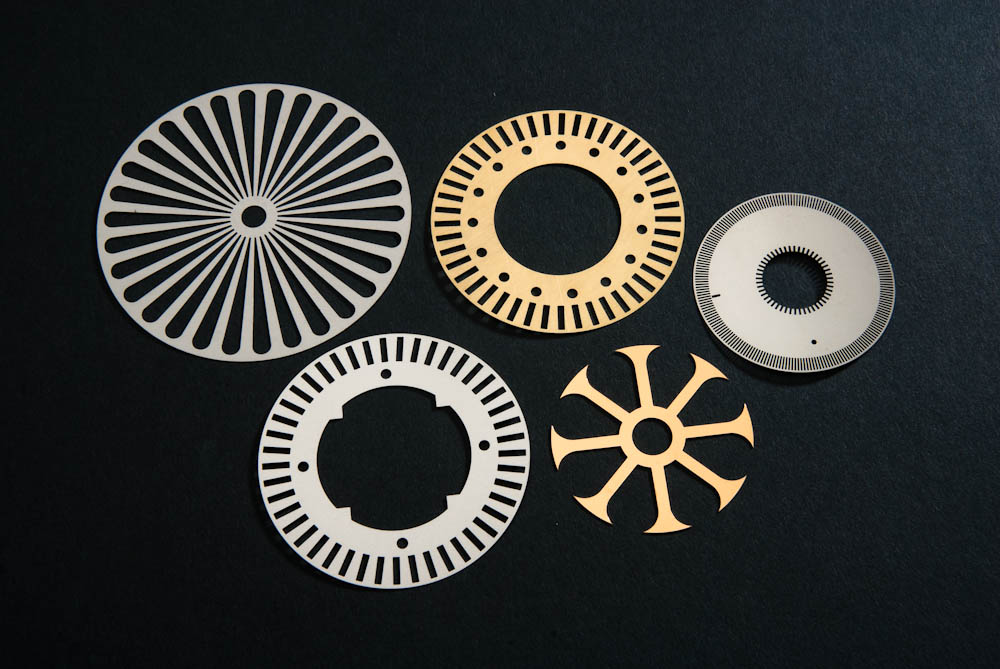

Aluminum nameplates are made with various metalworking techniques and come in several sizes and shapes. All aluminum nameplates are cut from aluminum stock. Manufacturing aluminum nameplates requires pressing, machining, and cutting. Once the plate is cut to the required dimensions, it undergoes additional shaping procedures. This includes bending, stamping, punching, and pressing.

Other processes include digital routing. Routing is creating consistent deep or through cuts on stiff materials, like aluminum or multi-layered plastic. This specialized cutting method provides tight tolerances and flawless edges for small to medium-quantity runs. Also, a guillotine can be used as a fast cutter that offers clean, precise cuts that are accurate to within a hair's breadth.

There are many ways to apply text and symbols on a freshly formed aluminum nameplate. Ink labeling is the simplest, most efficient type of nameplate labeling. Although blank aluminum nameplates are sometimes supplied in office supply stores and can be labeled, manufacturers can label them with precision machinery in a shop.

An aluminum nameplate can maintain long-lasting professionalism with expensive physical labeling techniques like stamping, etching, and engraving. An aluminum nameplate may undergo surface treatments to improve the nameplate's resistance to heat and corrosion. One such treatment is anodization, which makes the plates harder and more porous.

To boost the anodized coating and aluminum plate's wear resistance, manufacturers may occasionally raise the thickness of the plate. When text or images are screens printed on an aluminum nameplate, a chemical process opens the metal's pores, allowing the dye to permeate the metal's surface. Due to this process, the plate and graphics are sealed beneath the protective anodic layer.

Hole Punching: Hole punching is a typical feature of many aluminum nameplates. One can specify the size and placement of the holes and where they should be placed.

Round Corners: Manufacturers can add round corners without requiring specialized tools or a lengthy setup period. This removes the sharp corners that could hurt someone.

Benefits of Aluminum Nameplates

Because of this, aluminum nameplates are resistant to the elements and offer great protection against corrosion, solvents, and chemicals. The following are more benefits of aluminum plates.

- Their visuals are sealed for long-term readability

- Despite years of demanding use, the object is light and sturdy.

- nameplates can be attached to fasteners or other machinery with adhesives.

- In moist environments, anodized aluminum works better.

- Aluminum nameplates can be given an appealing finish.

Applications of Aluminum Nameplates

After purchase, nameplates are frequently affixed to equipment for identification. A business will frequently develop a standard template for the labels on their products. Many color, gloss, and font possibilities exist for name plates printed on aluminum. Aluminum nameplates are a desirable option for almost any warehouse, manufacturing, or office setting that needs equipment identification plates. Some equipment is regularly moved in a building setting aluminum's resistance to abrasion helps shield the plate surface from any touch.

Packaging labels. An organization will frequently attach a permanent nameplate that identifies the maker on a product as it is being prepared for shipping. Aluminum nameplates are often used in the aerospace, defense, energy, industrial, and manufacturing industries.

Choosing the Right Aluminum Nameplate Supplier

To ensure you have the most positive experience when purchasing aluminum nameplates from an aluminum nameplate supplier, it is important to compare several companies using our directory of aluminum nameplate suppliers. Each aluminum nameplate supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each nameplate supplier business using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple nameplate companies with the same form.

Laser Cutting

Laser Cutting Lasers

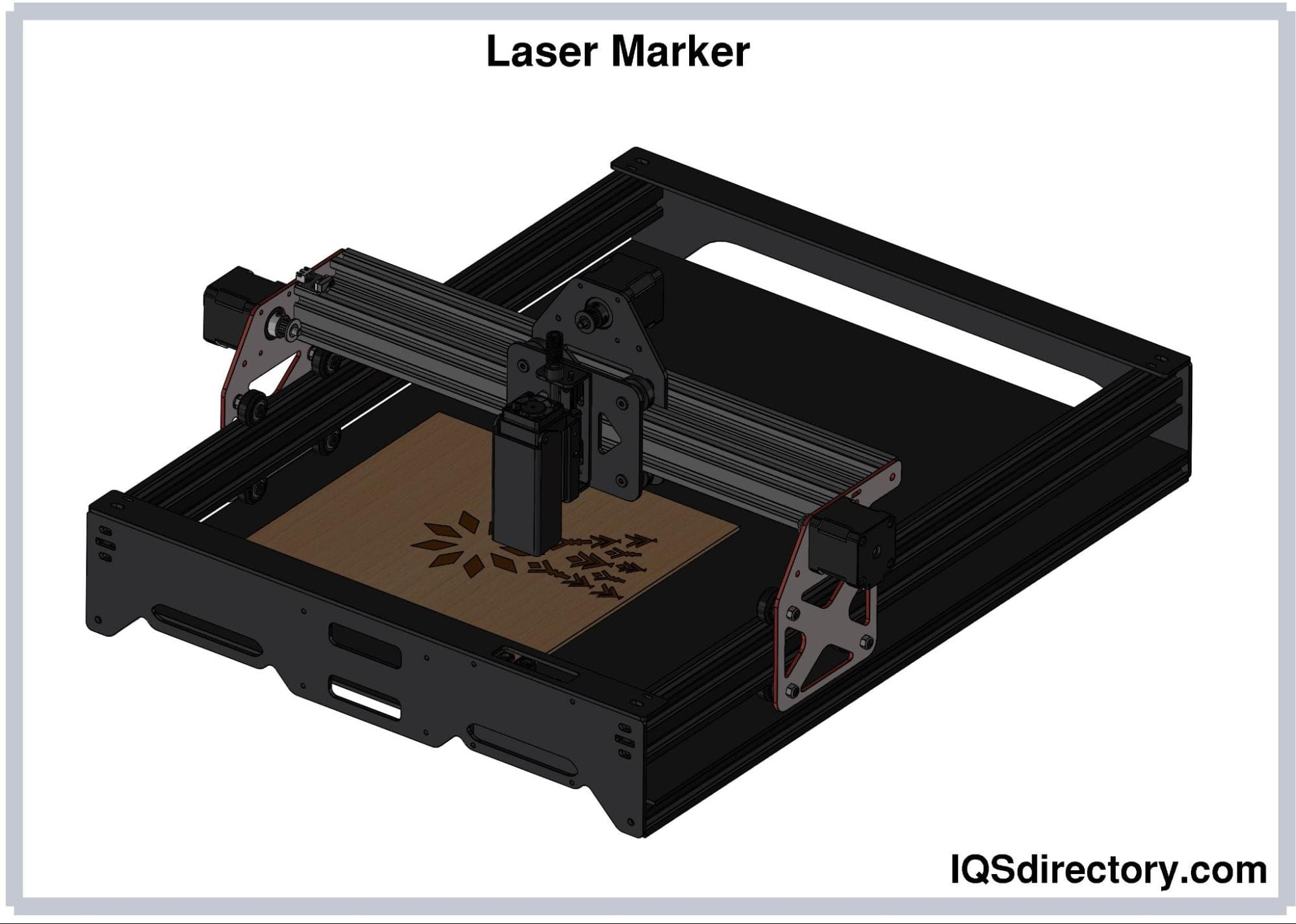

Lasers Marking Machinery

Marking Machinery Metal Etching

Metal Etching Name Plates

Name Plates Labeling Equipment

Labeling Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services