Metal nameplates are labels often used for industrial, commercial, and decorative purposes. They’re a daring approach for companies and people to imprint and mount messages. Metal nameplates can be made from over a dozen substrates, and molded to various sizes, scales, and thicknesses. They are affixed with various adhesives and finished with various polishes depending on the design and purpose. Read More…

At STRYKER, we take pride in designing and manufacturing precision name plates that serve as both identification and branding tools for a wide range of industrial and commercial applications. We understand that name plates are more than simple labels—they represent a company’s identity, quality, and attention to detail.

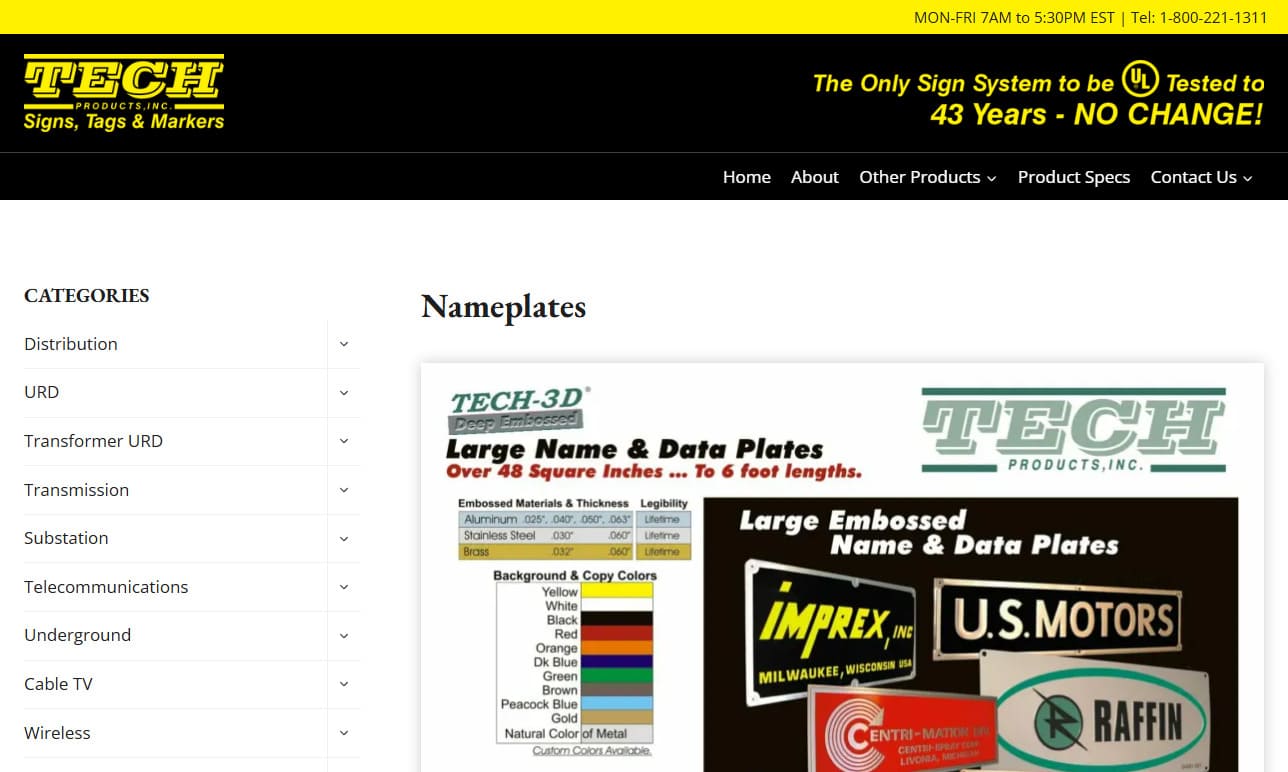

We are a manufacturer of identification products for original equipment manufacturer’s and utilities. For 75 years we have made pole tags, cable markers, data plates, safety signs and all things identification. Tech Products, Inc. provides the most durable products in our industries with brand names like EVERLAST, Tech-3D, FASTTAG, and TechBrite. We are also a service company – an information ...

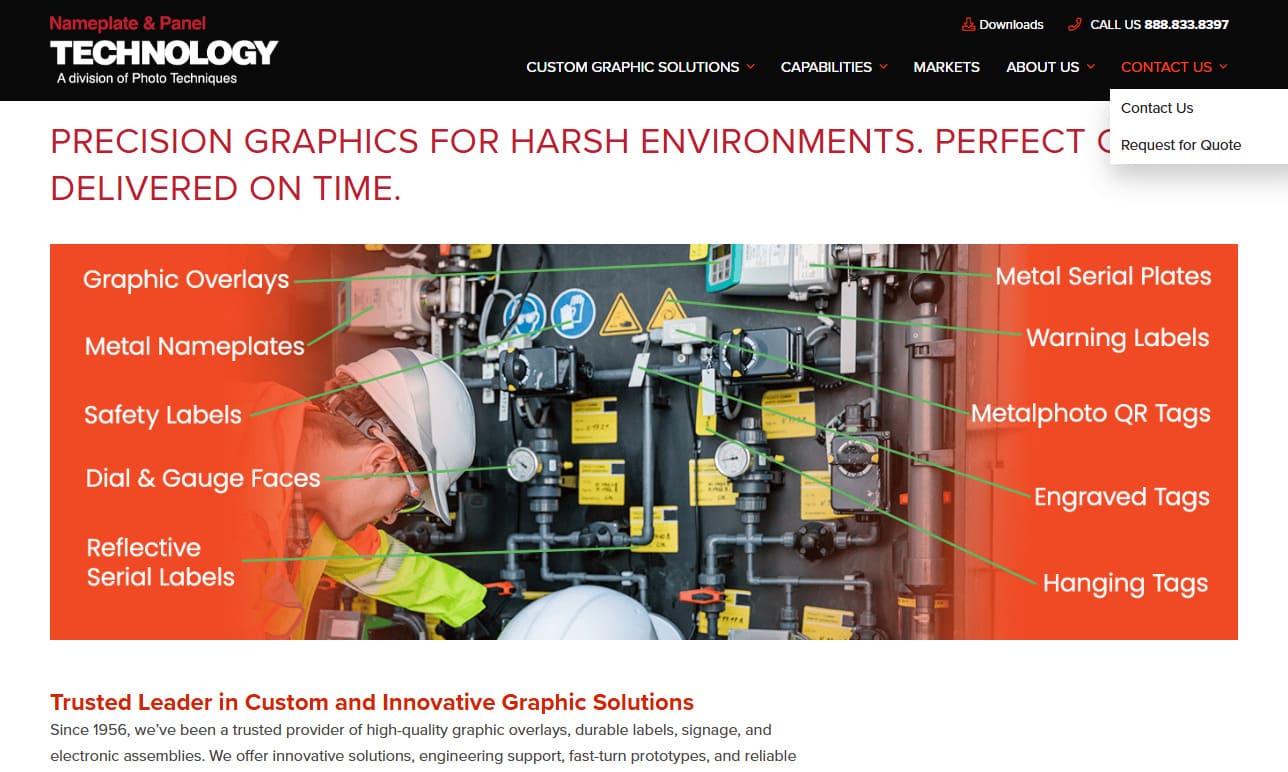

At Nameplate & Panel Technology, we are proud to be a leading provider of high-quality nameplates and panel solutions that meet the diverse needs of businesses across various industries. With decades of experience and a commitment to innovation, we have earned a reputation for excellence in the field of custom identification and labeling.

JN White is an ISO 9001:2015 and ITAR-certified manufacturer of name plates, graphic overlays, and custom labels. We nimbly handle projects big and small and have the uncommon ability to translate what our customers need into high-quality, high-precision outcomes. Our team's goal is to bring you the best through our dedication to quality and our constant pursuit of the latest technology. contact...

More Metal Nameplate Manufacturers

Metal nameplates are a versatile solution for organizational branding, product identification, and conveying critical information. Their defining characteristics are adaptability, exceptional durability, and the extensive branding possibilities they offer for organizations in various industries. A metal nameplate can be used to display information about a person, a room's contents or inhabitants, the location of an emergency escape in a structure, usage guidelines for a consumer product, or warning messages. Whether used for industrial equipment, office signage, safety compliance, or marketing, metal nameplates provide a professional, long-lasting method of communication that stands up to harsh environments.

The Design and Customization of Metal Nameplates

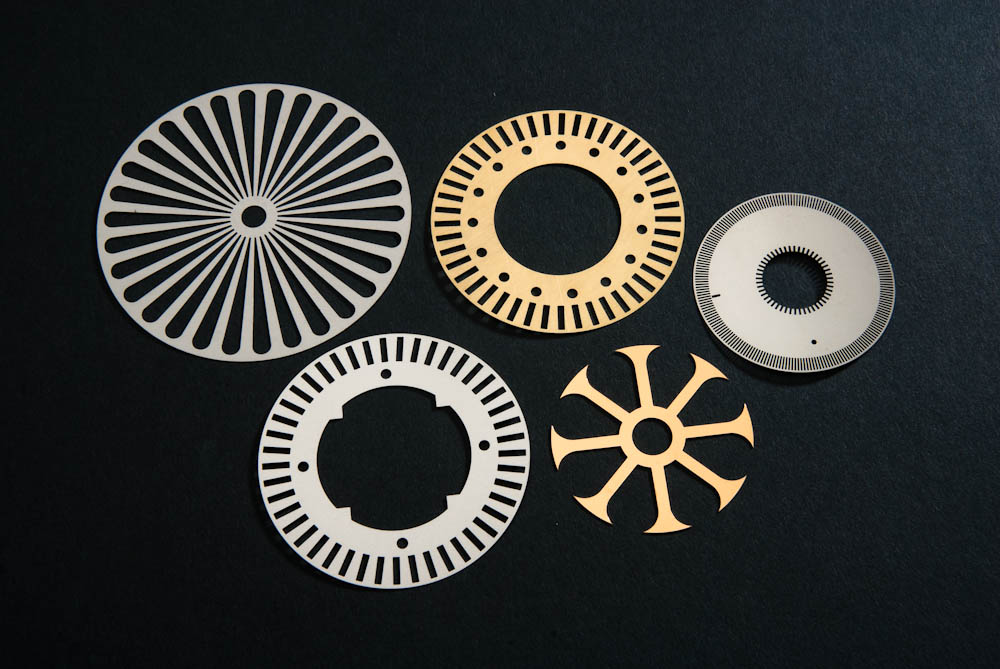

When it comes to custom metal nameplates, the design flexibility is vast, allowing organizations to tailor size, shape, finish, and information to their unique requirements. The most basic metal nameplates are constructed from thin aluminum sheets or other affordable metals. These are commonly attached to large consumer goods such as stoves, lawnmowers, and washing machines to provide directions for use, safety precautions, regulatory compliance information, and other pertinent data. The information is typically engraved, etched, screen printed, or stamped onto the metal surface, ensuring clarity and longevity.

Attachment methods are a key consideration in the design process. Fasteners or industrial adhesives can be used to affix nameplates to surfaces. For outdoor or high-moisture environments, mechanical fasteners are often preferred as they provide superior resistance to temperature fluctuations and humidity compared to some adhesives.

Most nameplates, including those used for personal or office identification, follow similar manufacturing processes. For example, a metalworker may stamp, etch, and then drill holes for fasteners in a stainless steel nameplate intended for use on an office door or as a desk nameplate. Metal nameplates can also be supported or suspended by frames, or used as free-standing desktop nameplates—a popular choice for executive offices and reception desks.

When selecting materials, it's important to consider the vulnerability of various metals to tarnishing and corrosion. Many metals require special care and protective finishes to maintain their appearance and functionality, especially for outdoor use or in industrial settings. Protective coatings, anodizing, or passivation treatments can greatly enhance the longevity of metal nameplates exposed to the elements.

Types of Metal Nameplates

Metal nameplates come in a wide variety of types, each serving distinct commercial, industrial, and personal identification applications. Choosing the right type is essential for maximizing functionality, brand impact, and regulatory compliance. Below are the most common types of metal nameplates, along with their primary uses and benefits:

Business Nameplates & Corporate Branding Plates

A company's name and logo displayed on a professionally crafted metal nameplate attract attention, project authority, and reinforce brand identity. Corporate nameplates can be installed in strategic locations such as office lobbies, boardrooms, and building entrances using either adhesive backings or sturdy wall fasteners. A trusted metal nameplate manufacturer can help scale down larger branding elements into compact logos or machine tags, ensuring consistent corporate branding across equipment, packaging, and marketing materials. High-quality business nameplates enhance credibility and create a lasting impression on clients and visitors.

- Lobby signage and office door plates

- Employee desk nameplates

- Building and suite identification markers

- Branding for trade shows and promotional displays

Permanently Affixed Warning Signs & Safety Plates

For industrial and commercial environments, metal nameplates can be transformed into durable, legal, and compliant safety signs. These include fire-exit labels, machine hazard warnings, eyewash station designations, PPE (Personal Protective Equipment) outfitting zones, and traffic route labels on warehouse floors. Metal warning plates are engineered to resist wear, abrasion, and fading, ensuring that critical safety information remains visible and legible for the life of the equipment or facility. Many industries, including manufacturing, chemical processing, and transportation, require metal safety signage to meet OSHA and ANSI standards.

- Compliance with safety and regulatory standards

- Long-term readability in harsh environments

- Custom shapes and sizes for application-specific needs

Equipment Labels, Tags & Weatherproof Instructions

Metal nameplates excel as equipment labels and tags, especially where weatherproof, tamper-resistant, or heat-resistant instructions are required. This is particularly beneficial for equipment installed in harsh environments, near sources of heat, or for machinery that requires immediate, on-the-spot operating instructions—such as metal valve plates, pump tags, or serial number plates in boiler rooms and factories. Engraved metal tags offer unmatched permanence and are ideal for asset tracking, maintenance scheduling, and field equipment management.

- Asset management and inventory tracking

- Maintenance and inspection tags

- Weatherproof and chemical-resistant labeling

Industrial Machine Labels & Heavy-Duty Nameplates

Industrial labels are among the most common applications for metal nameplates. From domestic and commercial appliances to heavy-duty equipment and machinery, these high-use, rugged items demand robust labeling solutions. Industrial machine labels must withstand repeated handling, exposure to chemicals, UV light, and extreme temperatures. Metal nameplates are often specified for these applications due to their strength, reliability, and compliance with industry labeling standards.

- OEM equipment labeling

- Control panel identification

- Compliance with UL, CSA, and CE requirements

Custom Engraved Metal Tags and Plates

For businesses seeking a unique touch, custom engraved metal tags and plates can be crafted in a variety of metals or two-toned engraver plastic hues to complement brand colors and aesthetics. These tags may include a company’s name, logo, contact information, and even QR codes for digital asset management. Customization options include laser engraving, rotary engraving, embossing, and color infill, ensuring a distinctive, eye-catching accessory that is also fade-resistant and built to last.

- Key tags and luggage tags

- Custom awards and recognition plaques

- Event badges and promotional items

Product Identification Plates with Serial Numbers

Product identification plates and serial number tags are critical for asset management, warranty tracking, and regulatory compliance. For products used in demanding and severe situations—such as construction equipment, medical devices, and transportation vehicles—product identifying information, serial numbers, and manufacturing data must remain legible for the lifespan of the product. Metal plates, especially those made from stainless steel or anodized aluminum, guarantee that the printed or stamped IDs are permanent, tamper-proof, and compliant with industry standards.

- Asset tags for fleet management

- Serial number plates for warranty and recall tracking

- Compliance with ISO, FDA, and DOT regulations

Materials Used for Metal Nameplates

The material selected for a metal nameplate directly impacts its performance, appearance, and cost. The most popular choices in the market include:

Stainless Steel Nameplates

Stainless steel is renowned for its strength, corrosion resistance, and attractive finish. It is widely used in environments where hygiene, durability, and appearance are paramount, such as medical device labeling, food processing equipment, and marine applications. Stainless steel nameplates maintain their integrity even under exposure to chemicals, saltwater, and extreme temperatures. They are an excellent choice for both indoor and outdoor use, offering a clean, professional look and exceptional longevity.

- Excellent resistance to corrosion and tarnish

- High strength and impact resistance

- Ideal for harsh or sanitary environments

Aluminum Nameplates

Aluminum is the second most popular material for metal nameplates. Its affordability, lightweight nature, and exceptional malleability make it ideal for customized nameplates that require fine engraving, embossing, or intricate designs. Anodized aluminum nameplates provide additional protection against weathering and chemicals, making them a popular choice for outdoor signage, electrical panels, and product labeling where both appearance and performance matter.

- Lightweight and cost-effective

- Anodizable for added durability and color options

- Suitable for high-volume production runs

Brass, Bronze, and Other Metal Nameplates

For applications where appearance and prestige are key—such as commemorative plaques, office signage, and luxury branding—brass and bronze nameplates offer a classic, elegant look. Although heavier and more costly than aluminum or stainless steel, these metals are valued for their aesthetic appeal and ability to be polished to a high luster. Gold and silver nameplates are used for artwork, high-end branding, and in executive offices, but are typically reserved for settings where cost is less of a concern than exclusivity.

- Brass: Warm gold color, often used for plaques and awards

- Bronze: Rich brown tone, ideal for monuments and memorials

- Gold/Silver: Used for premium, limited-edition applications

Applications of Metal Name Plates

Metal nameplates are utilized across a broad spectrum of industries and applications, thanks to their durability, versatility, and professional appearance. Common uses include:

- Product labeling for consumer electronics, appliances, and tools

- Nametags for employees, visitors, and event staff

- Desk and office nameplates for professional settings

- Architectural signage for buildings, monuments, and public spaces

- Equipment identification for industrial, medical, and laboratory assets

- Commemorative plaques and awards

- Regulatory compliance plates for machinery and vehicles

- Control panels and switch gear labeling

Many metals, including gold, silver, bronze, zinc, steel, and aluminum, can be used to make nameplates. Aluminum nameplates are especially popular for product labeling, desk plates, and signage due to their balance of cost and durability. Heavier metals like bronze and brass are often chosen for their aesthetic appeal in executive offices or as labels for monuments and artwork. Even more expensive materials, such as gold, are sometimes used for custom nameplates in high-end settings.

How to Choose the Right Metal Nameplate

Selecting the best metal nameplate for your application depends on several key factors. Carefully considering each of these will help ensure you get a nameplate that meets both functional and branding requirements:

- Environment: Will the nameplate be exposed to weather, chemicals, or extreme temperatures?

- Durability: Does the application require resistance to abrasion, UV, or moisture?

- Design: Is a particular shape, size, color, or finish required to match branding or aesthetics?

- Compliance: Are there regulatory or industry standards (such as OSHA, ANSI, UL, CSA) that must be followed?

- Attachment Method: Should the plate be fastened mechanically, with adhesive, or magnetically?

- Budget: What are the cost parameters for the project?

If you're unsure which material or design best suits your needs, consider these prompts to guide your research:

- What is the expected lifespan of your application?

- Do you require custom shapes, engraving, or color printing?

- Will the nameplate be used indoors, outdoors, or in a high-traffic area?

- Is tamper-resistance or security labeling required?

Benefits of Metal Nameplates

Metal nameplates are chosen for their many advantages over other labeling methods:

- Exceptional durability: Resistant to corrosion, weather, and abrasion

- Professional appearance: Enhances brand image and credibility

- Customization: Easily tailored to unique shapes, sizes, and brand colors

- Regulatory compliance: Meets industry standards for safety and asset identification

- Long-term value: Maintains legibility and appearance for years, reducing replacement costs

Interested in exploring how metal nameplates can improve your company's branding, safety, or compliance strategies? Discover top metal nameplate solutions and find the perfect fit for your industry.

Frequently Asked Questions About Metal Nameplates

- What is the lead time for custom metal nameplates? Lead times typically range from a few days to several weeks, depending on complexity, material, and order volume. Contact suppliers for specific turnaround times.

- Can I order metal nameplates with variable data or barcodes? Yes, many manufacturers offer variable data engraving, including serial numbers, barcodes, and QR codes for asset management.

- Are metal nameplates suitable for outdoor use? Absolutely. Stainless steel, anodized aluminum, and other treated metals are ideal for outdoor applications due to their corrosion resistance and durability.

- What finishing options are available? Finishes include brushed, polished, matte, painted, anodized, and powder-coated surfaces. Each finish can be tailored to aesthetic or performance needs.

- How do I choose between aluminum, stainless steel, and brass? Consider factors like environment, durability, cost, and appearance. For harsh or sanitary environments, stainless steel is best; for lightweight or cost-sensitive projects, aluminum is ideal; for prestige and aesthetics, brass or bronze may be preferred.

Choosing the Correct Metal Nameplate Supplier

To ensure you have the most beneficial outcome when purchasing metal nameplates from a metal nameplate supplier, it is important to compare several companies using our directory of metal nameplate suppliers. Each metal nameplate supplier has a business profile page highlighting their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each metal nameplate business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple metal nameplate companies with the same form.

How to Evaluate Metal Nameplate Manufacturers

When researching and evaluating metal nameplate manufacturers, consider the following decision factors to ensure you select a partner that aligns with your quality, timeline, and customization requirements:

- Does the manufacturer offer a robust selection of materials and finishes?

- Can they provide samples or prototypes before full-scale production?

- Do they have experience with your specific industry or compliance needs?

- Are advanced customization options like laser engraving, embossing, or color infill available?

- What is their reputation for quality control and on-time delivery?

- Do they provide assistance with design, layout, and compliance documentation?

Ready to request a quote or start your project? Contact metal nameplate suppliers now to discuss your requirements and receive competitive pricing from industry leaders.

Explore Metal Nameplate Options for Your Industry

Whether you need industrial equipment labels, office signage, safety compliance plates, or custom branding solutions, the right metal nameplate can add value at every level of your organization. Start by researching the options, materials, and suppliers that best match your specific application. Consider asking:

- What are the typical use cases for metal nameplates in my industry?

- Which materials meet my durability and branding requirements?

- Are there any regulatory standards my nameplates must satisfy?

- How can I maximize ROI with long-lasting, low-maintenance nameplates?

For more information, technical specifications, or to explore design ideas, visit our Metal Nameplate Resource Center and take the first step toward high-performance, custom metal nameplates tailored to your business needs.

Laser Cutting

Laser Cutting Lasers

Lasers Marking Machinery

Marking Machinery Metal Etching

Metal Etching Name Plates

Name Plates Labeling Equipment

Labeling Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services