Door name plates display details, label, or convey a message about a person, place, or room that the door encloses. Door name plates are often made of thin metal, wood, glass, or plastic. They are fastened to doors using magnets, Velcro, a slider, adhesive backing, nails, or screws. They often have a company logo or one to two lines of text. Read More…

Etched Metal Company takes pride in our expertise and precision in crafting exceptional name plates. With over 80 years of collective experience, we have mastered the arts of etching, anodizing, silk screening, and digital printing to create distinctive and durable identification solutions. Our commitment to excellence is reflected in every meticulous detail, ensuring that each name plate meets...

100 years of identification products for industry. DNPE meets any quality, durability & cost requirements with a full range of art & manufacturing capabilities. ID products include name plates, metal tags, custom decals, overlays, control panels, logo & barcode plates, UID tags, ASME plates, instruction plates, scales & dials, etc., utilizing aluminum, brass, MetalPhoto, stainless steel & vinyl.

Founded in 1923, Metal Marker Manufacturing is a manufacturer of name plates, custom metal tags, decals, metal photo products, and more. Numerous applications and industries have benefitted from our products, such as military, aerospace, and commercial. All products are made in the USA. With our ISO 9001 & AS9100 certification, our customers can be assured that they receive products of the...

At NFI Corp., we have been delivering quality nameplates since 1957. Our employees worldwide are dedicated to ensuring our customers’ deliver their high quality products to market, faster. Not only are we a customer driven company, but we strive for accountability and teamwork, we are committed to success and embrace change. For your next membrane keypads, call us today!

JN White is an ISO 9001:2015 and ITAR-certified manufacturer of name plates, graphic overlays, and custom labels. We nimbly handle projects big and small and have the uncommon ability to translate what our customers need into high-quality, high-precision outcomes. Our team's goal is to bring you the best through our dedication to quality and our constant pursuit of the latest technology. contact...

More Door Name Plate Manufacturers

Design of Door Name Plates

Because each name plate's text is unique, all nameplates are bespoke to some extent. Although sizes might vary, two by eight inches are the most typical measurements. To maintain consistency and organization, buildings with several door name plates arrange them according to a standard color, style, and font. The language on door name plates must be brief because they have little space. Industrial nameplates are made to withstand harsh temperatures, dampness, and chemical corrosion. In contrast, nameplates for public buildings and office doors are created with aesthetics and ornamentation in mind.

When it comes to door name plate design, there are many alternatives. They are produced from various materials, the most popular being copper, brass, or aluminum. Nameplates are painted or embossed with gold, silver, or black dyes to increase legibility. In addition, they are often polished or lacquered with a clear coating to improve resistance and attractiveness.

The majority of nameplate production is done using CNC-operated equipment. Plastic polymers used to make plastic door name plates can be developed and designed in any shape, color, texture, and configuration. Plastic nameplates are created using various techniques, including molding, etching, engraving, and embossing, much like all other plastic items. Plastic is the perfect material for name plates because of its strength and affordability.

How Door Name Plates Are Made

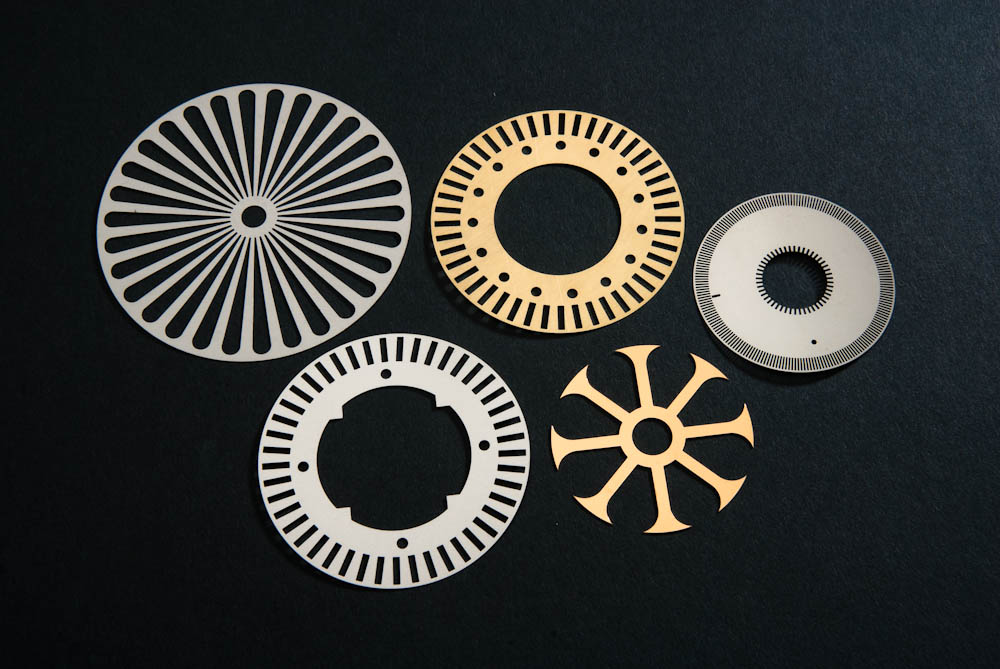

Etching

An acid is used to eat away at the metal plate's surface to generate a nameplate with an intricately recessed image. A waxy substance covers the areas of the metal that are not etched to provide protection. While the metal is submerged in the etching solution, the acid eats the undesirable metal. As a result, the image gets more distinct the longer the metal is in the acid.

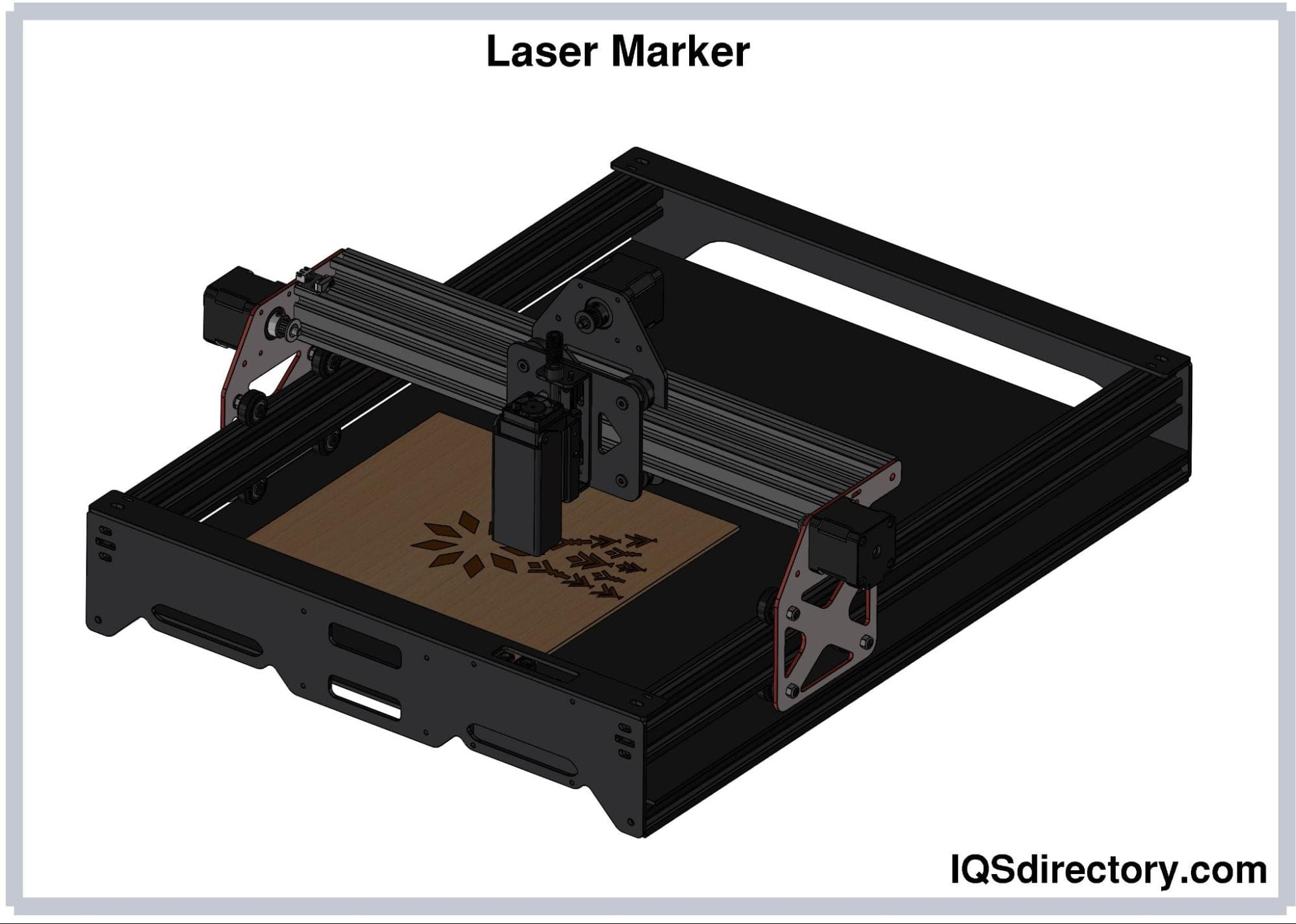

Engraving

Metal engraving involves cutting, digging, scraping, or gouging the metal's surface to carve an image or design. A laser marking system or CNC equipment creates designs by engraving. Engraving was an artistic endeavor that required highly skilled artisans before the advent of computerized technological procedures.

Embossing

Embossing imprints words & designs into metal by applying pressure and force. The metal is sandwiched between two die halves and squeezed to create the impression. The embossed image is permanently imprinted on the metal workpiece by compressive force. The finished product is a raised text readable, precise, long-lasting, and resistant to environmental stressors.

Types of Name Plates

Standard nameplates are rectangular, but manufacturers can customize them into other shapes. In addition, screen printing can be used to apply paint or ink to the text.

The most popular technique for creating three-dimensional writing involves wearing away the surface of the unique text design using chemicals, diamonds, needles, or lasers. As a result, fonts etched or embossed are easier to read and last considerably longer than printing. Plastic nameplates are hot stamped using a ram that has the necessary text molded into it.

Customized Door Name Plates

Vintage, architectural nameplates have been used for decades. It is the most traditional and most effective nameplate concept. However, the concept of modular nameplates is becoming popular. A modular nameplate has a shelf affixed to it. Any object, including religious items, can be kept there. Nameplates with a 3D embossed foundation provide an exquisite appearance, transforming the house's overall appearance. Homeowners may choose to embellish their nameplates.

Applications of Door Name Plates

To guide visitors, door nameplates are frequently used in public facilities such as schools, colleges, hospitals, medical centers, and religious structures. In addition, nameplates are used in workplaces, including offices, factories, and warehouses, to increase professionalism and organization.

Choosing The Correct Door Nameplate Supplier

To ensure you have the most positive outcome when purchasing door name plates from a door nameplate supplier, it is important to compare several companies using our directory of door nameplate suppliers. Each door nameplate supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each door nameplate business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple door nameplate companies with the same form.

Laser Cutting

Laser Cutting Lasers

Lasers Marking Machinery

Marking Machinery Metal Etching

Metal Etching Name Plates

Name Plates Labeling Equipment

Labeling Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services